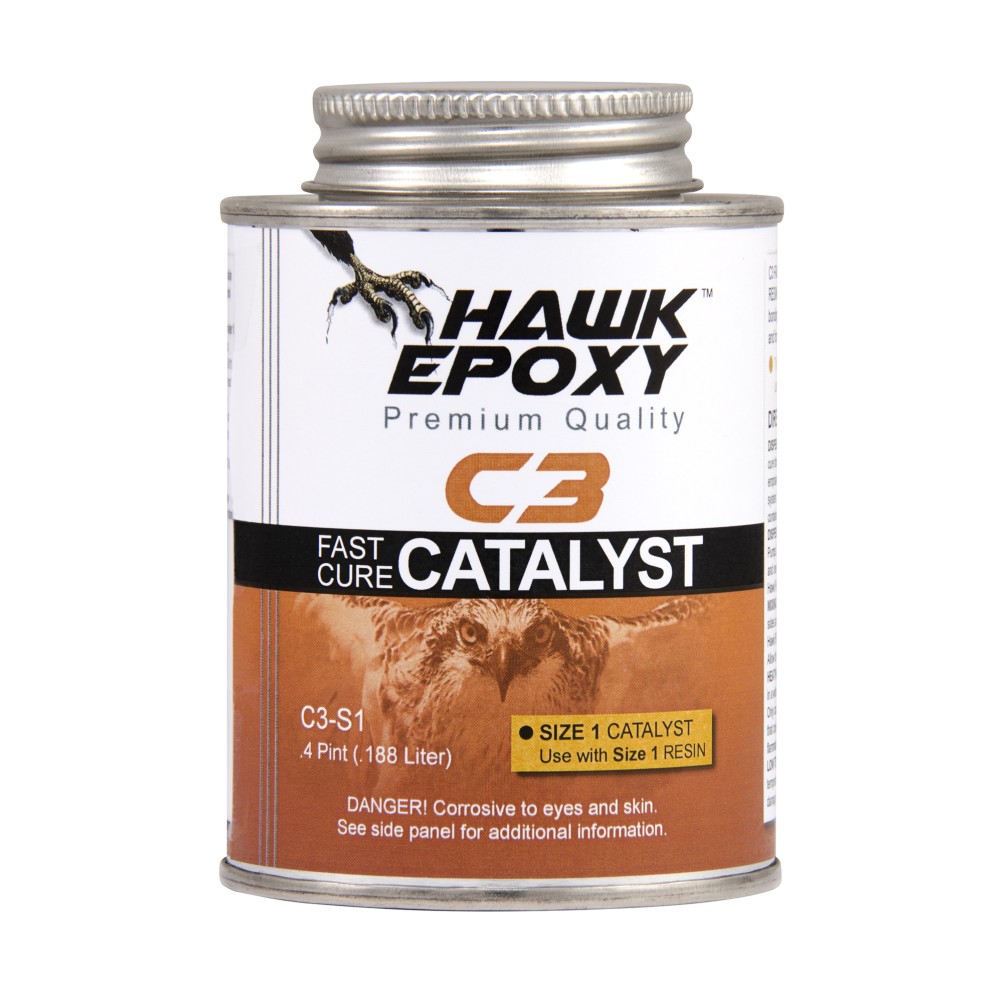

Hawk Epoxy Fast Cure Catalyst, C3-S1, .4 Pint

-

Boat Bottom Paint

- Top Performing Bottom Paint

- Self-Polishing-Ablative Bottom Paint

- Hard Bottom Paint

- Hybrid Bottom Paint

- Water Based Bottom Paint

- Aluminum Safe Bottom Paint

- Bottom Paint Primers

- Specialty Marine Coatings

- Outdrive Paint

- Sea Hawk Paints

- Blue Water Bottom Paints

- Interlux Bottom Paint

- Pettit Bottom Paint

- Bottom Paint Remover

- Aquagard Bottom Paints

- Cleaners-Reducers-Solvents

- Boat Paint

- Boat Zincs

- New Items and Specials

- Boat Bottom Paint3

- Fiberglass and Gel Coat Repair

-

Topside Boat Paint

- Above or Below the Waterline

- Aluminum Boat Paint

-

Awlgrip Marine Paint

- Awlgrip Polyester Urethane Topcoat

- Awlcraft 2000 Acrylic Urethane Topcoat

- Awlgrip Awlcraft® SE Topcoat

- Awlgrip HDT

- Awlcraft 3000

- Awlgrip Converters

- Awlgrip Reducers and Activators

- Awlgrip Primers/Sealers

- Awlgrip Fairing/Surfacing

- Awlgrip Awl-Prep Wipe Down Solvents

- Awlgrip Corrosion Inhibiting Surface Treatments

- Awlgrip Brightwork, Varnish, Interior Wood

- Awlgrip Auxiliary Products

- Awlgrip Maintenance Products

- Camouflage Boat Paint

- Blue Water Topside Paints

- Duralux Marine Paints

- Marine Enamels

- Interlux Topside Paint

- Pettit Easypoxy

- Adhesives and Sealants

- Teak Oil and Wood Restoration

- Boat Paint Supplies

- Resins

- Cleaners and Polish

- Manufacturers

- Propeller and Running Gear Coatings

Your shopping cart is empty!

Product Description

C3-S1 Fast Cure Catalyst - .4 Pint Size 1

Hawk Epoxy Technical Data Sheet

*This Item Ships From Florida Click to see Estimated Transit Times

Preparation: Apply over clean, dry surfaces. Remove all grease, oil, wax, or other foreign material by solvent, such as, S-80 Wax N Grease Killer or detergent washing. (SSPC-SPI). Non-porous substrates must be sanded to create a rough surface for stronger bonding and adhesion. Remove all dust prior to application.

DISPENSING: Do not adjust ratio (R1 Epoxy Resin/Catalyst) to alter cure time. Use the exact mixing ratio as described on page 2 of this document or on the Catalyst Label. Ensure accurate measuring for maximum properties. Particular emphasis was placed in the overall strength and toughness of the cured system. Dispense into a clean, non-porous, straight-sided plastic or metal container. Foam and glass container are unsuitable.

Dispensing with Hawk Pumps: If using the calibrated 30-KT Hawk Pumps, the correct ratio will be dispensed by one pump push of Catalyst and one pump of R1 Resin to equal the correct ratio. See the 30-KT Hawk Pump Manual for more details.

MIXING: Stir R1 Epoxy Resin and desired Hawk Epoxy Catalyst well ensuring that all materials from sides and bottom of container are thoroughly mixed for one to two minutes. Then include any Hawk Epoxy Filler (F1 High Load Adhesive Filler, F2 Structural Adhesive Filler, F3 Light Density MicroFiber Filler, F4 Bridging Adhesive Filler, F5 Light Density Fairing Filler, F6 MicroSphere Fairing Filler) if desired depending on application. Allow for adequate ventilation.

Application Tip: Unless you plan on overcoating Hawk Epoxy (when color variations may not matter), use the same age Hawk Epoxy Catalyst on a particular project to ensure color consistency.

HEAT WARNING! Curing epoxy generates heat and should be mixed in a wide shallow container to increase the surface area of the mixture. Only combine R1 Hawk Epoxy Resin and Hawk Epoxy Catalyst in small batches to reduce to avoid excessive exothermic heat that could shorten the working time melting or igniting the container or flammable materials and damage the skin.

HIGHER TEMPERATURE WARNING: Hawk Epoxy R1 Epoxy Resin will cure faster in warmer temperatures. DO NOT alter mix ratio to compensate for temperature. Doing so could damage the cure and reduce the strength of the epoxy

LOWER TEMPERATURE WARNING: Extra cure time is required as ambient temperature decreases. Using R1 Epoxy Resin below 40°F (4°C) could damage the cure and reduce the strength of the epoxy. DO NOT alter mix ratio to compensate for temperature.

CLEANUP: Clean up R1 Hawk Epoxy Resin, and mixed epoxy resin and Hawk Epoxy Catalyst with S-80 Wax N Grease Killer, acetone, or MEK.

SPILL/LEAK: Use an inert absorbent to complete clean-up. This material reacts with oxidizing materials. Take up carefully to avoid heat and sparks.

STORAGE: Storage temperature: 40°-90°F (32°-4ºC). Keep containers sealed and in a well-ventilated area. Hawk Epoxy Catalysts, (C1 Ultra Slow Catalyst, C2 Slow Cure Catalyst, C3 Fast Cure Catalyst, and C5 Clear Finish Catalyst) will darken in color with extended storage times. However, this color change will in no way affect the physical characteristics of the finished project. Hawk Epoxy R1 Resin may thicken with extended storage times and may require thorough mixing before combining with Hawk Epoxy Catalysts. If R1 Hawk Epoxy Resin or a Hawk Epoxy Catalyst goes through extreme hot and cold temperatures, 32˚F or below, it may get hard and mineralized in appearance. The mineralization will in no way affect the physical characteristics of the finished product. To eliminate mineralization, heat product to no less than 110˚F for 1-2 hours. Hawk Epoxy components have an extended shelf life that will last for several years. After extended storage, be sure to mix a small amount of R1 Hawk Epoxy Resin and Hawk Epoxy Catalyst (at correct ratio) and ensure proper curing before proceeding to a larger scope project.

Hawk Epoxy C3 Fast Cure Catalyst Safety Data Sheet

CHARACTERISTICS AND PROPERTIES

Mix by volume :...............................................................5.0 : 1

Mix by weight: ..................................................................5.3 : 1

Viscosity (at 77°F) :..........................................................75—85 KU

Pot life (6 oz at 77°F):.......................................................9-12 mins

6 mils DD tack/ not wet (77°F):.........................................60-70 mins

6 mils DD cured (77°F ):...................................................6-8 hrs

6 mils DD Full cured (77°F ):...........................................1-4 days

Minimum T at application:................................................40°F (4°C)

Weight/gallon (lb/gal) :...................................................... 9.41

Hardness (Shore D):........................................................83

Peak Load (lbf):................................................................650.6

Peak Stress (MPa):..........................................................68.9

Modulus (MPa):................................................................3776

Chord modulus Strain 1-2 (Pa):........................................3472

Elongation at peak (in):....................................................0.067

Elongation at peak (%).....................................................3.4

Elongation at Break (%):..................................................4.5

Energy to break (J):..........................................................4.9

Break Stress (MPa):.........................................................61.6